RESOL Technology specializes in the manufacturing of engineered products, delivering customized solutions based on designs from technology providers, customer specifications, or our proprietary innovations. Our state-of-the-art facilities support fabrication, machining, assembly, and testing, catering to industries such as power, cement, mining, and infrastructure. We produce high-quality components, modular skids, and specialized equipment, ensuring precision, durability, and compliance with global standards.

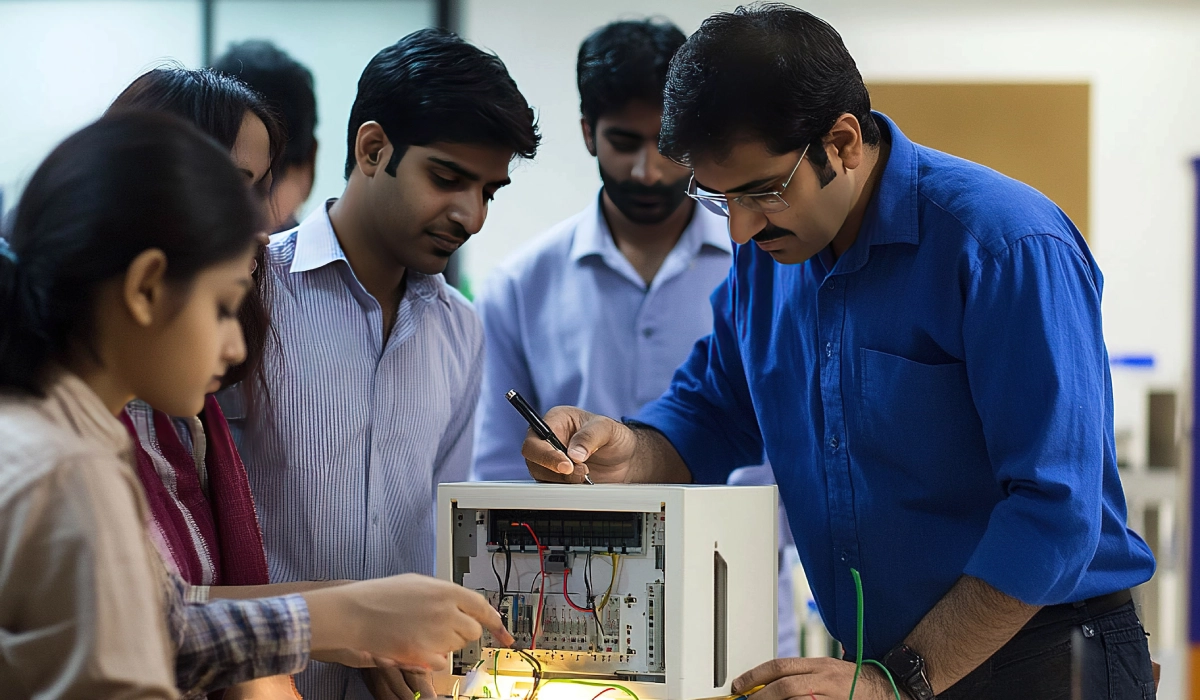

Our engineered products manufacturing process begins with a collaborative design phase. For client-specific designs, we work closely with customers to refine specifications, ensuring alignment with project requirements. When partnering with technology providers, we adapt licensed designs to meet local standards and operational needs. For proprietary products, our in-house R&D team develops innovative solutions, leveraging advanced engineering tools like 3D modeling, CAD, and finite element analysis (FEA). This ensures optimal performance under demanding conditions, such as high temperatures, pressures, or corrosive environments.

RESOL’s manufacturing capabilities are comprehensive. Our workshops are equipped with CNC machines, robotic welding systems, and precision machining tools, enabling us to produce complex components like pressure vessels, heat exchanger parts, and OEM replacement parts. We fabricate modular skids for process systems, integrating piping, valves, and instrumentation for plug-and-play installation. Our facilities also support heavy-duty fabrication, producing structural frames, jigs, and fixtures for industrial applications.

Quality assurance is central to our manufacturing process. We adhere to stringent QA/QC protocols, including ISO 9001 and ASME standards. Each product undergoes rigorous testing, such as non-destructive testing (NDT), hydrostatic testing, and dimensional inspections, to ensure defect-free performance. Our materials—sourced from trusted global suppliers—meet specifications like ASTM, DIN, and IS, ensuring corrosion resistance and mechanical strength. For critical components, we provide certification and traceability, supporting compliance with regulatory and client requirements.

RESOL’s engineered products are tailored to diverse applications. In power plants, we manufacture turbine components, boiler parts, and cooling system modules. For cement plants, we produce kiln supports, grinding mill parts, and conveyor components. In mining, we deliver crusher parts, conveyor rollers, and wear-resistant liners. Our custom jigs and fixtures enhance construction efficiency, while our proprietary designs, such as energy-efficient pump skids, reduce operational costs. We also produce OEM replacement parts, ensuring compatibility with existing systems and minimizing downtime.

Sustainability is a key focus. We optimize material usage to reduce waste and incorporate eco-friendly coatings to extend product life. Our manufacturing processes comply with ISO 14001, minimizing environmental impact. Energy-efficient machining and lean production techniques lower our carbon footprint, aligning with global sustainability goals. We also design products for recyclability, supporting circular economy principles.

RESOL’s project management ensures seamless execution of manufacturing projects. We use tools like MSP and ERP for scheduling, inventory management, and cost control. Our multidisciplinary teams—comprising engineers, machinists, and quality inspectors—coordinate closely to meet tight timelines. For large-scale orders, we implement just-in-time (JIT) production, reducing storage costs and ensuring on-time delivery. Our global supply chain network enables rapid sourcing of raw materials, even for exotic alloys or specialty components.

Post-manufacturing, we offer comprehensive support, including installation guidance, commissioning assistance, and aftermarket services. Our technical teams provide on-site training for safe operation and maintenance, while our spare parts management ensures long-term availability. We also conduct performance audits to optimize product efficiency, extending service life. With a track record of delivering engineered products across India, Africa, and Southeast Asia, RESOL is a trusted partner for EPC manufacturing needs.

Our commitment to innovation sets us apart. By investing in R&D, we develop next-generation products, such as IoT-enabled components for predictive maintenance. Our partnerships with technology providers enable us to integrate cutting-edge solutions, like AI-driven process skids. For customers, our bespoke manufacturing ensures perfect fit and function, enhancing project outcomes. Whether producing a single prototype or high-volume components, RESOL delivers precision, reliability, and value.